Cone Crusher Princle

Cone crusher basics in 4 minutes SRP

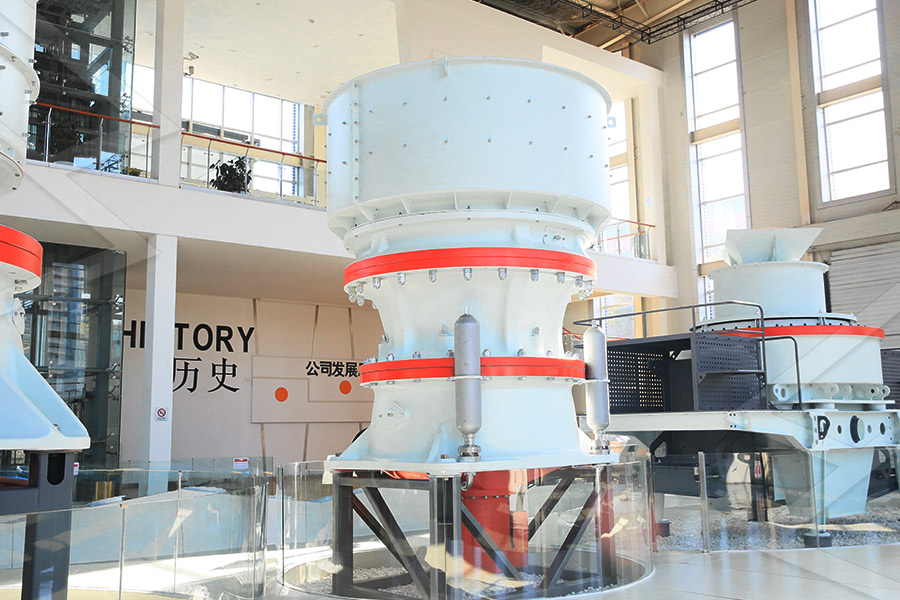

This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but The main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp release mechanism (mechanically or hydraulically actuated)Cone Crushers (Parts of a Cone Crusher) 2023年2月23日 A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces But how does it work? In this article, we'll explore the cone crusher working principle, including Understanding the Cone Crusher Working 2023年2月21日 In this comprehensive guide, we'll explain the working principle of a cone crusher, its components, maintenance tips, benefits, and offer practical advice on how to choose the right cone crusher for your applicationUnderstanding the Cone Crusher Working

Cone Crusher SpringerLink

2023年5月3日 Cone crusher is a type of crushing equipment whose crushing cone rotates in the conical cavity within the shell to realize intermediate crushing or fine crushing of material 2024年7月15日 Summary: This exhaustive guide delves into the core elements of cone crusher technology, offering insights into its operational principles, innovative design traits, What is a Cone Crusher?SBM Industrial Technology Group2024年9月29日 The working principle of a cone crusher is based on the concept of compressive force As the material enters the crushing chamber, the mantle moves in a circular motion, 6 Frequently Asked Questions About Cone Crusher2022年1月14日 Commonly used crushers include jaw crusher, impact crusher, hammer crusher, cone crusher, etc This article will introduce the working principles of these four types of crushing machines one by one to help you Working Principle of 4 Commonly Used Crushers

Understanding Cone Crusher Parts: Names,

2023年2月22日 Cone Crusher Basics and Working Principle Cone crushers consist of several components that work together to achieve efficient and effective crushing The following are some of the basics of cone crushers and their 2022年12月12日 The unique working principle of cone crusher enables it to be useful for primary crushing, secondary crushing and final crushing as wellWhat Is the Cone Crusher Working Principle?This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but Cone crusher basics in 4 minutes SRPThe main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp release mechanism (mechanically or hydraulically actuated)Cone Crushers (Parts of a Cone Crusher)

.jpg)

Understanding the Cone Crusher Working

2023年2月23日 A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces But how does it work? In this article, we'll explore the cone crusher working principle, including 2023年2月21日 In this comprehensive guide, we'll explain the working principle of a cone crusher, its components, maintenance tips, benefits, and offer practical advice on how to choose the right cone crusher for your applicationUnderstanding the Cone Crusher Working 2023年5月3日 Cone crusher is a type of crushing equipment whose crushing cone rotates in the conical cavity within the shell to realize intermediate crushing or fine crushing of material Cone Crusher SpringerLink2024年7月15日 Summary: This exhaustive guide delves into the core elements of cone crusher technology, offering insights into its operational principles, innovative design traits, What is a Cone Crusher?SBM Industrial Technology Group

6 Frequently Asked Questions About Cone Crusher

2024年9月29日 The working principle of a cone crusher is based on the concept of compressive force As the material enters the crushing chamber, the mantle moves in a circular motion, 2022年1月14日 Commonly used crushers include jaw crusher, impact crusher, hammer crusher, cone crusher, etc This article will introduce the working principles of these four types of crushing machines one by one to help you Working Principle of 4 Commonly Used Crushers 2023年2月22日 Cone Crusher Basics and Working Principle Cone crushers consist of several components that work together to achieve efficient and effective crushing The following are some of the basics of cone crushers and their Understanding Cone Crusher Parts: Names, 2022年12月12日 The unique working principle of cone crusher enables it to be useful for primary crushing, secondary crushing and final crushing as wellWhat Is the Cone Crusher Working Principle?

.jpg)

How Does a Cone Crusher Work and What is It?

2024年3月15日 The cone crusher’s intricate transmission system makes it possible for it to perform its vital function The crushing cone’s axis experiences a powerful swing when the eccentric sleeve rotates Importantly, this swinging 2024年1月1日 Cone crusher is a type of crushing equipment whose crushing cone rotates in the conical cavity within the shell to realize intermediate crushing or fine crushing of material through squeezing, bending, shearing, and impacting At the end of the nineteenth century, the Simons brothers of the USA invented this equipment based on gyracone crusher Cone Crusher SpringerLinkThis cone crusher is often utilized in the second, third or fourth stage of the crushing process Designed for your needs, the new generation HP4™ is safe and easy to maintain Guard protection, a new liner attachment and the lack of Nordberg® HP4™ cone crusher Metso2022年9月15日 Nordberg HP800 Cone Crusher Stationary : One HP500, one HP300, two HP200 crushing "Amphibolite" Higher yield By operating the HP cone crusher on the lower end of its speed range, the product gradation can be shifted to produce fewer fines and a higher percentage of onspec product The HP cone crusher creates a higher value product with less Nordberg Cone Crushers HP Series Cone Crushers

.jpg)

Cone Crusher Diagram: Simplified Guide JXSC

2024年3月19日 A cone crusher is a super important machine used in mining and construction It’s designed to break down big rocks, ores, and other stuff into smaller pieces that are easier to handle The machine gets its name from its conelike shape, which has a fixed outer cone called the bowl liner and a moving inner cone known as the mantle 2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution The Complete Guide to Primary Crushing, Secondary 2023年8月2日 Cone crushers Cone crushers are one of the main choices for secondary crushing A cone crusher is a powerful machine that is used in largescale industries for crushing various types of materials into smaller sizes It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and forceTypes of Crushers: What You Need to Know HUATAO GROUP2023年7月31日 A cone crusher is crucial, especially in aggregates and mining industries It plays a role in crushing hard rocks into smaller rocks for further processing Understanding how a cone crusher operates is essential to optimize its performance to achieve effective crushing This article will delve into the components of the cone crusher, its application, operation, []How Does A Cone Crusher Work: Understanding The

.jpg)

Working Principle of Crushers 911Metallurgist

2016年2月18日 Working Principle of Crushers On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher In order to understand the crushing action in such a chamber it is helpful to consider the process as though each step took place in an orderly, and In summary, the Short Head Cone Crusher’s working principle is based on gyratory crushing, which allows for efficient and effective crushing of hard and abrasive materials Its unique design and adjustability make it a valuable asset in various industrial applicationsUnderstanding the Working Principle of Ore Crusher Short 2021年3月15日 The good performance of the cone crusher is mainly reflected in the high productivity and neat particle size distribution of crushed products There is a strong coupling relationship between productivity optimization and product quality optimization models Based on the principle of interparticle breakage, the kinematic characteristics of bulk Chamber Optimization for Comprehensive Improvement of Cone Crusher Symons compound cone crusher is a modern high performance crusher designed and developed by EASTMAN according to the needs of users, based on the principle of lamination crushing and the concept of more crushing and less Symons Cone Crusher Eastman Rock Crusher

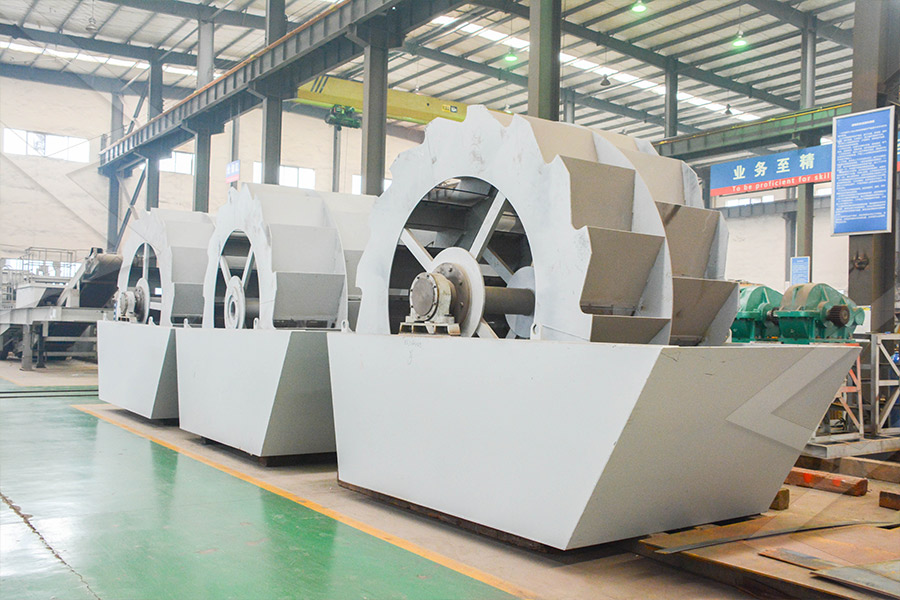

Construction, Working and Maintenance of Practical

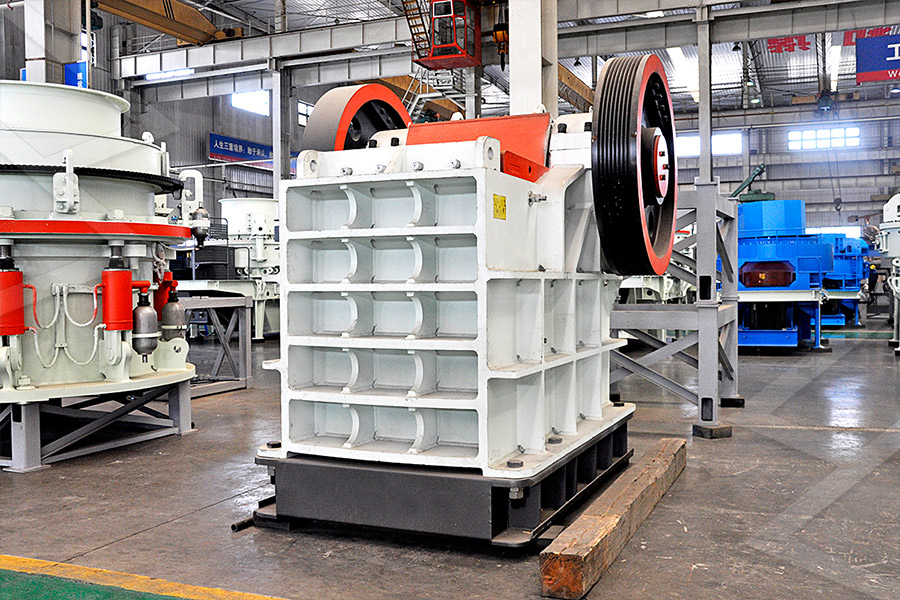

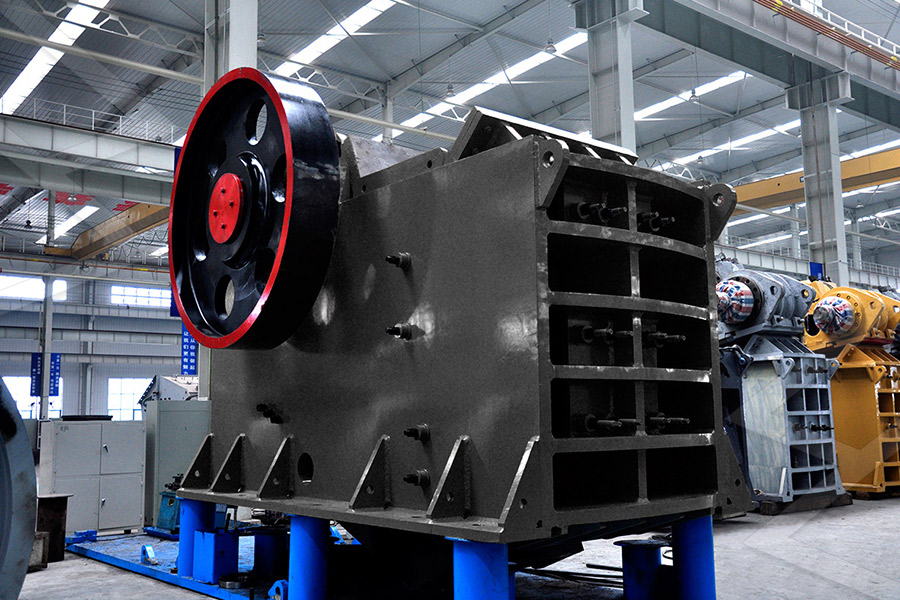

2018年12月26日 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Breakers 48 10 Manganese Steel 49 The goal of a crusher is to crush the given material in to the material with certain size and shape Information about crushing technology, construction, working and maintenance of 2023年3月11日 Another advantage of using an impact crusher is that it has a relatively low operating costThe machine uses less energy than other crushers, such as jaw or cone crushers, and its impact force is more efficient at breaking down the material, resulting in less energy wasteHow Impact Crushers Work: A Comprehensive Guide AGICO2023年2月15日 The mobile cone crusher is designed to be easily transported between sites and is usually mounted on tracks, which provides flexibility in terms of the types of terrain that it can operate on Additionally, the mobile cone crusher is equipped with a range of features that make it highly efficient and easy to operateA Comprehensive Guide to Cone Crusher Types AGICO2022年1月14日 Jaw crushers are widely used in mining, smelting, building materials industry, highways, railways, water conservancy and chemical industries and many other sectors, crushing various materials with compressive strength within 320 MPa Working Principle Jaw crusher mainly consists of a frame, an eccentric shaft, a large pulley, a flywheel, a movable jaw, a side Working Principle of 4 Commonly Used Crushers miningpedia

.jpg)

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers It is often the case that there will be only one crusher installed, and this will be referred to as the ‘Primary Crusher’ Cone crushers are typically used for 2 nd, 3 rd 4 th stage crushing steps (although not always)Gyratory Crusher (Gyratory Crushers Explained) saVRee%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resources2023年9月12日 Working principle of cone crusher Under the action of the driving force of the electric motor, the pulley and the Vbelt, the cone crusher starts to work When the cone crusher is working, the drive shaft starts to What is a cone crusher? SBM Mill Crusher

Cone Crushers 911Metallurgist

2018年6月1日 Introduction Compared to the gyratory crusher, the cone crusher is characterized by its higher speed and a flat crushing chamber design which is intended to give a high capacity and reduction ratio for materials suitable to this type of processing2020年11月8日 Singlecylinder VS Multicylinder Hydraulic Cone Crusher 44 45 Gyratory Crusher 45 Cone Crusher 46 Cone and Impact Crushers 46 47 Mobile Cone Crusher / Cone Crushing Plants 47 48 iii) Impact Crusher 48 49 Impact Crusher; Crushing; and Classification Equipment2023年2月28日 Gyratory cone crushers are powerful machines that have revolutionized the crushing industry Their unique design and superior performance make them a popular choice for a wide range of applications, from mining and construction to recycling and chemical processing In this article, we explore the many advantages of gyratory cone crushers, including their high Unveiling the Advantages and Applications of Gyratory Cone 2020年1月6日 The Cone Crusher plays an important role in different industries, such as construction industry, chemical industry and metallurgical industry It can be used to crush both hard and medium hard materials, such as 3 SHREE CONMIX ENGINEERS PVT LTD MOBILE NO : 79088, PHONE: 079 , FAX: SHREE CONMIX ENGINEERS PVT LTD CONE CRUSHER

Nordberg HP Series cone crushers – High performance

2022年1月21日 Nordberg® HP Series™ cone crushers The world's most popular modern cone crushers Nordberg HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design As the name suggests, these proven and reliable universal crushers deliver High Performance in quarrying and mining applicationscone crusher,spring cone crusher,cone crusher working principle Spring Cone Crusher Working Principle Driven by the electricmotor ,the eccentric shaft bush will rotate with the triangle belt,small and big bevel gear,big bear Cone Crusher Working Principle2023年5月27日 Cone crusher: $5, 000/ Set (the lowest price) Contact us 3 The overall structure of the machine From the perspective of the overall structure, the cone crusher is 172 times heavier and 23 times higher than the jaw crusher with the same feeding opening sizeJaw Crusher VS Cone Crusher (A Comparison From 7 Points)A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand Since its inception, the liveshaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone crushing and its robust Our Range of Trio® Cone Crushers Weir Weir Group

.jpg)

Cone Crusher Spring Cone Crusher

2023年5月2日 Cone Crusher, Fig 1 Structural diagram of gyradisc cone crusher 2 Cone Crusher equipment from damage The crushing cavity has highperformance noncontact labyrinth seal to resist dust more reliably, reduce dust pollution and equipment abrasion, and prolong service life of equipment The main shaft of multicylinder